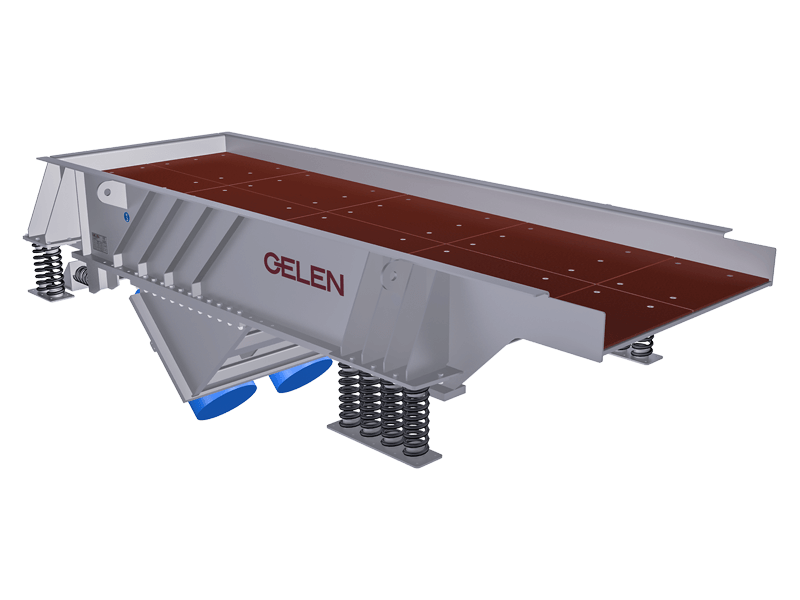

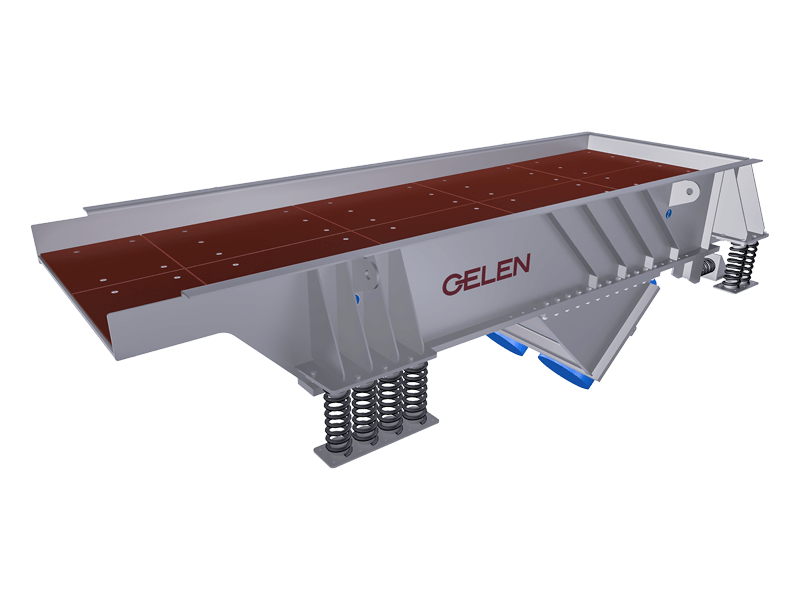

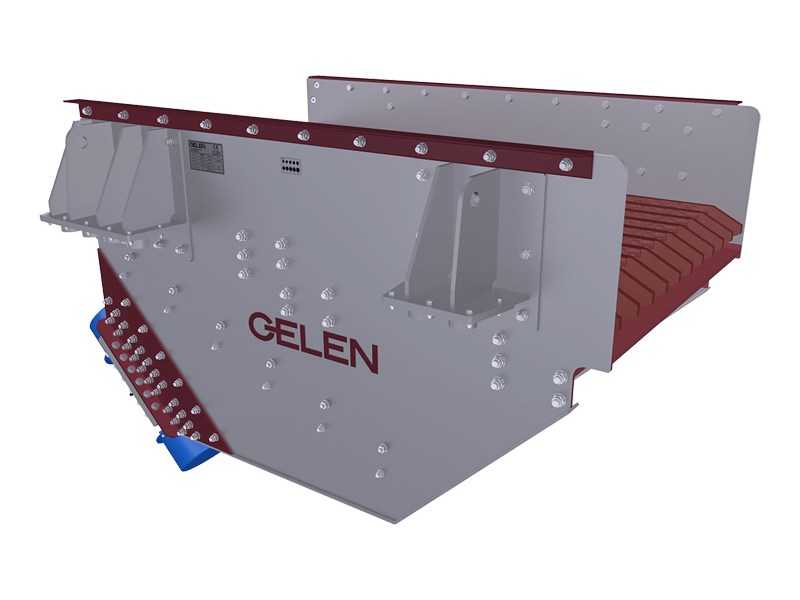

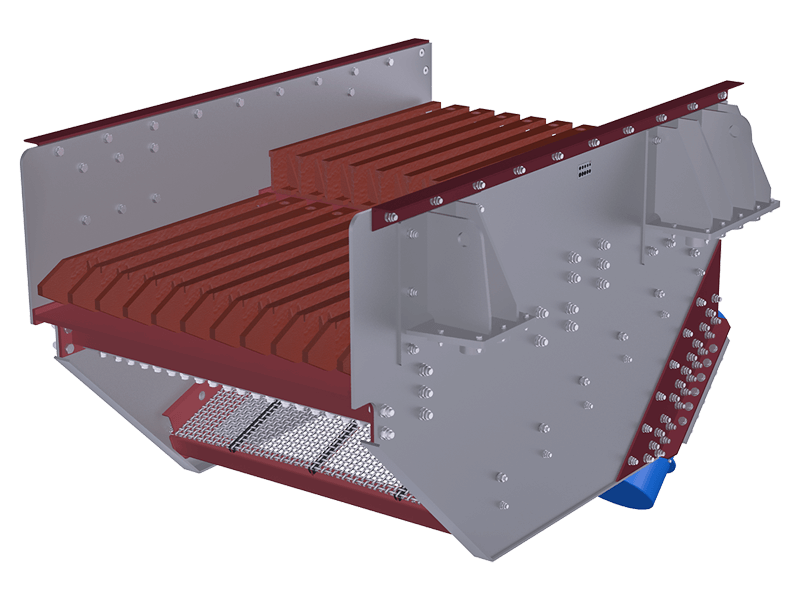

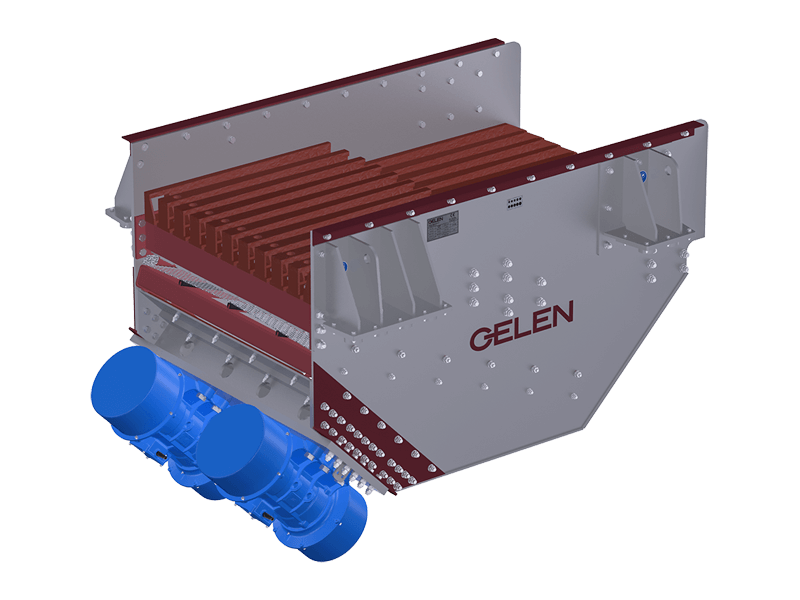

TB SERIES VIBRATING FEEDERS

Smooth, uniform feeding of the material is crucial for the efficiency in a crushing plant. Having this in mind, GELEN vibrating feeders are designed to give the best feeding solutions with different sized crushing equipment. High feeding capacity and success with hard and abrasive materials make GELEN feeders ideal for the customer.